Dry ice is a solid form of carbon dioxide (CO2) that is found naturally in the atmosphere. Unlike regular ice, dry ice will not melt in your hands. It exists between -80 degrees Celsius and -109 degrees Celsius.

Dry ice cleaning is a simple and effective way to clean parts without chemicals, abrasive materials, high temperatures, or steam. CO2 pellets are used as impact medium for removing surface contamination from parts with no damage to your equipment.

Dry ice cleaning uses a blast media that sublimates (vaporizes) upon impact with the surface. All that remains is the contaminate you are removing, and since dry ice vaporizes on impact, the process can be used to clean complicated cavities where typical grit blast media will become trapped.

Dry ice cleaning offers a safe and effective method for surface cleaning and preparation. Unlike other blast media, dry ice has a temperature of -109°F (-78.3°C). Because of the temperature difference between the dry ice particles and the surface being treated, thermal shock occurs during the process of dry ice blasting. This causes a breakdown of the bond between two dissimilar materials. Gummy substances and adhesives are embrittled making them easier to remove

Dry contaminants can be swept up or vacuumed, whereas a wet contaminant is removed by the force of the stream.

Dry ice cleaning works by using compressed air to accelerate dry ice pellets to high speeds, which then impact the surface to be cleaned. The rapid expansion and contraction of the dry ice pellets as they hit the surface causes the dirt and contaminants to break away and be removed.

Dry ice cleaning is a non-abrasive, non-toxic, and non-flammable cleaning method that can remove dirt and contaminants without damaging the underlying surface. It is also a cost-effective and efficient cleaning method, as it can often eliminate the need for chemicals or solvents.

Yes, dry ice cleaning is safe when performed by trained professionals and with proper safety precautions. Dry ice is non-toxic and non-flammable, and the cleaning process does not produce any hazardous waste.

Dry ice cleaning is a non-abrasive, non-toxic, and non-flammable cleaning method that can remove dirt and contaminants without damaging the underlying surface. It is also a cost-effective and efficient cleaning method, as it can often eliminate the need for chemicals or solvents.

Dry ice is made by compressing and cooling carbon dioxide gas to extremely low temperatures, at which point it turns from a gas to a solid.

Dry ice cleaning can be used on a wide range of surfaces, including metal, plastic, wood, and even delicate surfaces like electronic components.

The duration of the dry ice cleaning process will depend on the size of the area to be cleaned and the amount of dirt and contaminants present. A typical cleaning process can take anywhere from a few minutes to several hours.

Yes, dry ice cleaning can be used on delicate or sensitive surfaces, as it is a non-abrasive cleaning method.

Dry ice blasting and dry ice cleaning are essentially the same thing; the terms are often used interchangeably. Both refer to the process of using dry ice pellets to clean surfaces.

The cost of dry ice cleaning will depend on several factors, including the size of the area to be cleaned, the amount of dirt and contaminants present, and the cost of the dry ice cleaning equipment and materials. Contact us for a free quote.

Dry ice cleaning is a non-abrasive, non-toxic, and non-flammable cleaning method, while sandblasting and pressure washing can be abrasive and may use chemicals or solvents. Dry ice cleaning also leaves behind no secondary waste, while sandblasting generates a lot of abrasive waste and pressure washing generates waste water.

Yes, dry ice cleaning can be used for mold remediation, as it is effective at removing mold and mold spores from surfaces without spreading them to other areas.

Dry ice cleaning is an environmentally friendly cleaning method, as it does not use chemicals or solvents and does not produce any hazardous waste. The carbon dioxide used in the dry ice pellets is a natural and safe substance.

Yes, dry ice cleaning can be used to remove graffiti, as it is effective at removing paint and other substances from surfaces without damaging the underlying surface.

Dry ice cleaning is a non-toxic and non-flammable cleaning method, while solvents and chemicals can be toxic and flammable. Dry ice cleaning also leaves behind no secondary waste, while solvents and chemicals can generate hazardous waste.

Safety precautions for using dry ice cleaning equipment include wearing protective gear, such as goggles and gloves, and properly training employees on the use of the equipment. It’s also important to ensure that the dry ice is stored and handled correctly, as it can cause skin and eye irritation and frostbite if handled improperly.

Yes, dry ice cleaning can be used for food processing equipment, as it is effective at removing food debris and other contaminants from surfaces without leaving behind any residue.

Dry ice cleaning is a non-toxic and non-flammable cleaning method, while hot water and steam cleaning can use chemicals or solvents. Dry ice cleaning also leaves behind no secondary waste, while hot water and steam cleaning can generate waste water.

Yes, dry ice cleaning can be effective for removing heavy industrial buildup, as it is effective at removing dirt, grime, and other contaminants from surfaces.

Yes, dry ice cleaning can be used to clean HVAC systems, as it is effective at removing dirt and debris from ducts and other components without damaging the underlying surface.

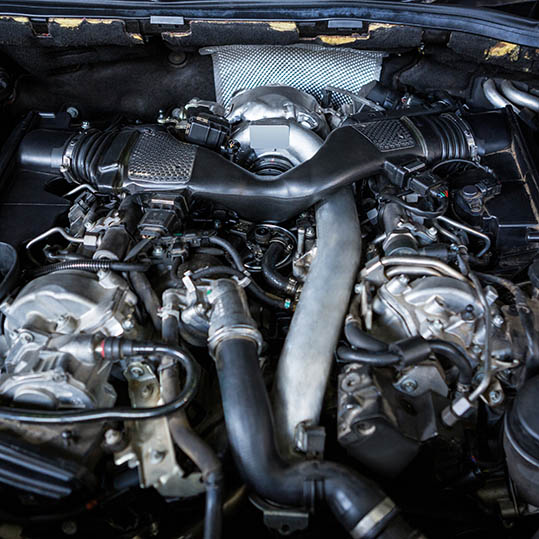

Yes, dry ice cleaning can be suitable for cleaning automotive parts, as it is a non-abrasive, non-toxic, and non-flammable cleaning method that can remove dirt and contaminants without damaging the underlying surface.

Dry ice cleaning is a non-abrasive, non-toxic and non-flammable cleaning method, while pressure washers can be abrasive and may use chemicals or solvents. Dry ice cleaning also leaves behind no secondary waste, while pressure washers can generate waste water. Additionally, dry ice cleaning can be effective at removing hard-to-remove substances such as adhesives, graffiti, oil and grease. It can also be used to clean surfaces that are sensitive or delicate in nature, that may get damaged by high pressure or abrasive methods.

Dry ice cleaning is often a cheaper alternative than other forms of media cleaning. The cleaning process has a fast turn around time and allows for less to no downtime. The nonabrasive results allow for extra steps to be eliminated, saving you money.

Dry ice cleaning has three factors contributing to its effectiveness: First, is thermal impact. At a temperature of -109ºF, dry ice causes thermal shock of the surface due to the difference in temperature. This causes the bond between the contaminant and the surface to break leaving a clean surface behind. Second, there is kinetic impact, as dry ice pellets bombard each other off of its surface. Third, as sublimation of dry ice takes place, it expands 800% propelling the contaminant off the substrate

Dry ice cleaning will remove rust, surface rust, oxidation and salts (SP 6). The dry ice does not remove deeply adhered corrosion or pitted oxidation. Dry ice is simply not aggressive enough to create a profile or a white metal finish.

Yes! dry ice cleaning will clean the car’s surface as much as possible without causing damage to the exterior paint. In fact, it just requires one quick rinse after using dry ice blasting to wash away any residue and you’re ready to buff.

Dry ice cleaning is nonabrasive. This means it will not damage your surface during removal. Sandblasting can be a very abrasive method, which can cause damage to your surface while removing materials.

Dry ice cleaning is a non-abrasive cleaning method, while abrasives and wire brushing can be abrasive and can damage surfaces. Dry ice cleaning also leaves behind no secondary waste, while abrasives and wire brushing can generate waste.

Yes, dry ice cleaning can be used to remove paint or coatings, as it is effective at removing paint and other substances from surfaces without damaging the underlying surface.

The recommended cleaning intervals for dry ice cleaning will depend on the amount of use and the level of dirt and contaminants present. Contact us and we can help determine the appropriate cleaning schedule.

Yes, dry ice cleaning can be used to clean electronics or machinery, as it is effective at removing dirt, dust, and other contaminants without damaging the underlying surface.

Dry ice cleaning is a non-abrasive, non-toxic and non-flammable cleaning method, while high-pressure washers can be abrasive and may use chemicals or solvents. Dry ice cleaning also leaves behind no secondary waste, while high-pressure washers can generate waste water.

Yes, dry ice cleaning can be suitable for cleaning historic or heritage buildings, as it is a non-abrasive, non-toxic, and non-flammable cleaning method that can remove dirt and contaminants without damaging the underlying surface.

Dry ice cleaning is a non-abrasive cleaning method, while sandblasting can be abrasive and can damage surfaces. Dry ice cleaning also leaves behind no secondary waste, while sandblasting can generate waste.

Yes, dry ice cleaning can be used to clean solar panels, as it is effective at removing dirt, dust, and other contaminants from the surface of the panels without damaging them.

Dry ice cleaning is a non-abrasive, non-toxic and non-flammable cleaning method, while power washers can be abrasive and may use chemicals or solvents. Dry ice cleaning also leaves behind no secondary waste, while power washers can generate waste water.

Yes, dry ice cleaning can be suitable for cleaning aircraft or aerospace components, as it is a non-abrasive, non-toxic, and non-flammable cleaning method that can remove dirt and contaminants without damaging the underlying surface.

Yes, dry ice cleaning can be used to remove oil and grease, as it is effective at breaking down and removing these types of contaminants from surfaces.

Dry ice cleaning is a non-abrasive, non-toxic and non-flammable cleaning method, while hot water pressure washers can use chemicals or solvents and can generate waste water.

Yes, dry ice cleaning can be suitable for cleaning medical equipment, as it is a non-abrasive, non-toxic, and non-flammable cleaning method that can remove dirt and contaminants without damaging the underlying surface.

Dry ice cleaning is a surface cleaning method, while steam cleaning uses hot water vapor to remove contaminants. Dry ice cleaning is effective for removing dirt and grime and is non-abrasive, while steam cleaning is more effective in removing particulate matter and can also remove bacteria and other microorganisms. Steam cleaning also requires more time and resources to heat up the water and generate steam, while dry ice cleaning can be done more quickly and efficiently.

Yes, dry ice cleaning can be used to remove adhesives or stickers, as it is effective at breaking down and removing these types of contaminants from surfaces without damaging the underlying surface.

Dry ice cleaning is a non-toxic and non-flammable cleaning method, while solvent cleaners can be toxic and flammable. Dry ice cleaning also leaves behind no secondary waste, while solvent cleaners can generate hazardous waste.

Yes, dry ice cleaning can be suitable for cleaning in sensitive environments, as it is a non-toxic, non-flammable and non-abrasive cleaning method that can remove dirt and contaminants without damaging the underlying surface or generating any hazardous waste.

Dry ice cleaning is a non-abrasive cleaning method, while wire brushing can be abrasive and can damage surfaces.

Yes, dry ice cleaning can be used to remove rust or corrosion, as it is effective at breaking down and removing these types of contaminants from surfaces without damaging the underlying surface.

Dry ice cleaning is a non-toxic and non-flammable cleaning method, while chemical cleaners can be toxic and flammable. Dry ice cleaning also leaves behind no secondary waste, while chemical cleaners can generate hazardous waste.

Yes, dry ice cleaning can be suitable for cleaning in hard-to-reach areas, as it can be done with specialized equipment that can access tight spaces.

Dry ice cleaning uses dry ice pellets as the blasting media, while traditional blasting methods use abrasive materials such as sand, glass beads or aluminum oxide. Dry ice cleaning is non-abrasive, leaves no secondary waste, and is safe to use on sensitive surfaces.

Yes, dry ice cleaning can be used to remove fire damage or soot, as it is effective at removing these types of contaminants from surfaces without damaging the underlying surface.

Dry ice cleaning is a non-abrasive cleaning method, while sandblasting can be abrasive and can damage surfaces. Dry ice cleaning also leaves behind no secondary waste, while sandblasting can generate waste.