No Water. No Chemicals. No Damage.

Ontario’s Dry Ice Cleaning Specialist.

Dry Ice Blasting delivers

Jaw-dropping Results

Dry ice cleaning (Dry Ice Blasting) is a remarkably safe, eco-friendly, and exceptionally effective method of cleaning. It harnesses the power of solid CO2 to eliminate dirt, grease, and other impurities from a variety of surfaces, including metal, plastic, wood, and even sensitive electronic components. Using a high-pressure blast of dry ice, this technique pulverizes grime, making it effortless to remove.

Dry ice cleaning is an ideal solution for a wide range of cleaning challenges and provides a powerful and efficient cleaning solution. It’s uses no water, or chemicals, is environmentally friendly and will not leave harmful residue behind.

How Does Dry Ice Cleaning Work?

Dry ice blasting works by using high-pressure compressed air to accelerate dry ice pellets to supersonic speeds. The dry ice then strikes the surface to be cleaned, causing the dirt, grime, and other contaminants to be removed without damaging the surface. The dry ice sublimates (turns from a solid to a gas) upon impact, leaving no residue behind. This makes dry ice blasting a safe and effective cleaning method for a wide range of industries.

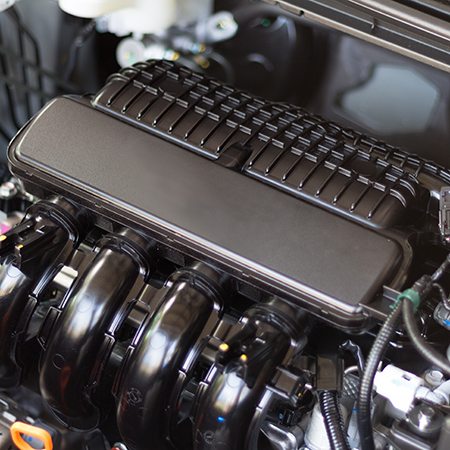

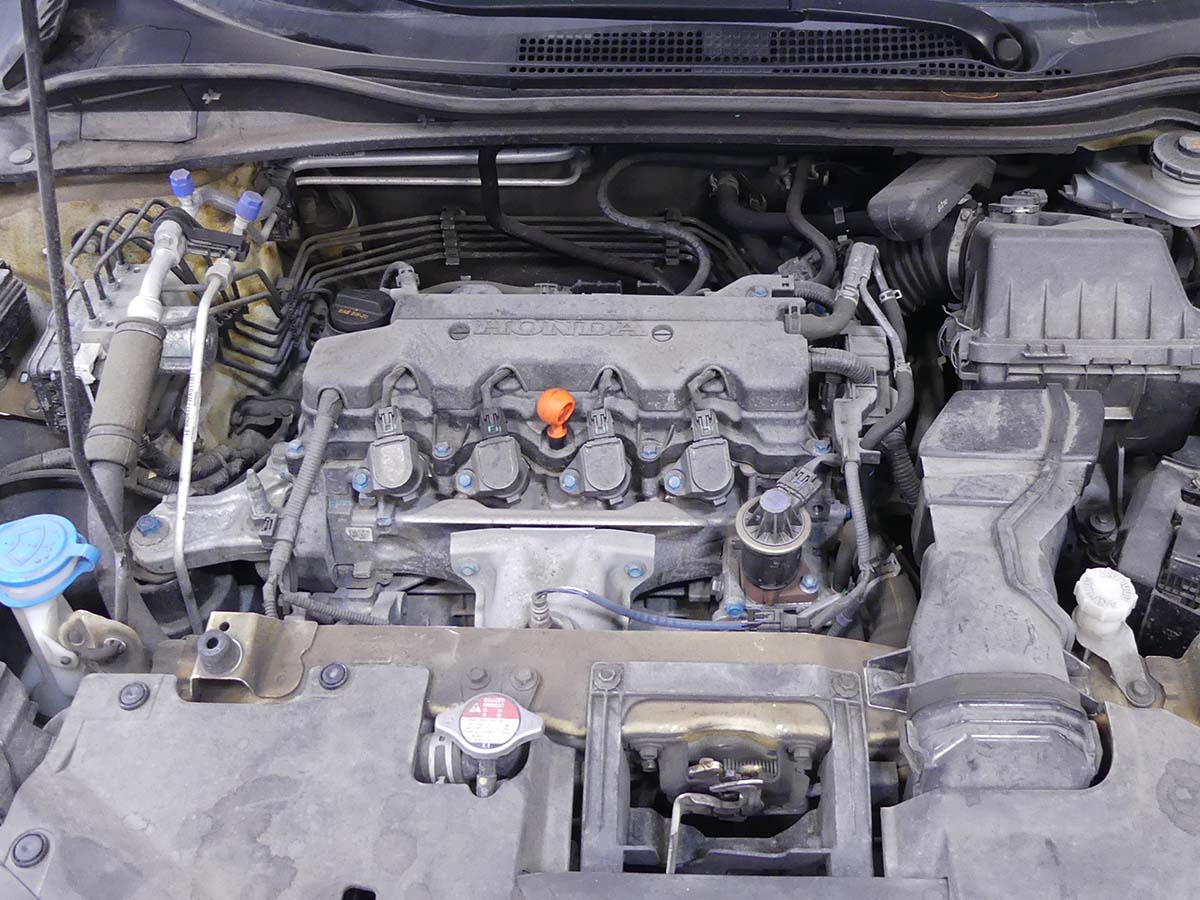

Before & After Dry Ice Cleaning

Slide the white line above to see before and after dry ice blasting.

Dry Ice Cleaning to the rescue!

Benefits of Dry Ice Cleaning

Chemical Free Cleaning

Dry ice cleaning does not produce secondary waste streams, residue or moisture.

No Water

Dry Ice cleaning is a waterless cleaning process that instantly vaporizes during the blast cleaning process, leaving behind no residues.

Superior Clean

Remove heavy buildup on everything, including metal and steel without the need for chemicals.

Non-abrasive

Unlike traditional cleaning methods that can damage surfaces, dry ice blasting is non-abrasive. This makes it ideal for cleaning delicate surfaces and machinery.

Environmentally sustainable

Dry ice is made of recycled CO2 and does not add additional CO2 to the atmosphere. It also significantly reduces water use for sanitation.

Quick and Efficient

Dry ice cleaning is a quick and efficient cleaning method. It can clean large surfaces in a fraction of the time it takes with traditional methods.

we love them

what our clients have to say

“Lorem ipsum dolor sit amet, contur ading elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.”

Sophie LeonardCEO shark

“Lorem ipsum dolor sit amet, contur ading elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.”

Herman NortonStudio Director

“Lorem ipsum dolor sit amet, contur ading elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.”

Amanda ParksCYBERO

Meet Our Clients

They Believe In Us

Lorem ipsum dolor sit orot amet, consectetur adip scing

elit. Proin rutrum euismod dolor, ultricies aliq luam off

kool or taka ekolor.

Dry Ice Cleaning can clean almost anything.

What Can Dry Ice cleaning Do?

Dry ice cleaning is an effective, efficient, and environmentally friendly method for car cleaning & detailing. If you’re looking for a powerful and effective way to return your vehicle to near factory condition try dry ice cleaning.

Dry ice cleaning is a revolutionary cleaning method that eliminates the risk of damaging sensitive parts and delivers a deep clean. It eliminates the risk of removing paint or plating, or overheating components with high heat. The process is environmentally friendly and will not leave harmful residue behind.

Dry ice cleaning is a much safer, more efficient way to remove adhesive buildup on production equipment. The low temperatures of dry ice weaken the bond between the adhesive and surface, enabling for faster removal. Dry ice cleaning is non-abrasive and does not produce secondary waste, which leads to more regular cleaning and prolonged equipment life.

Dry Ice cleaning reduces waste and dust, keeping costs down. With no flash rusting or rust inhibitors required, the surface will be left dry and residue-free so you can apply a new coating more quickly.

Dry ice blasting is an excellent tool for cleaning composite molds, as it extends the life of molds and tooling by cleaning without the need for harsh chemicals, wire brushes or coarse pads. The process keeps critical dimensions and geometric shapes of parting lines and sealing surfaces intact, while also preserving the mold surface finish.

Dry ice cleaning is a fast and effective way to clean all types of production equipment. Instead of damaging surfaces, creating secondary waste or harming your employees or the environment, our dry ice blast cleaning method cleans even the most difficult and previously unapproachable components.

Historical restoration with dry ice cleaning is a safe, non-abrasive and cost-effective way to restore historical items. The process eliminates manual cleaning with abrasive hand tools, harmful chemicals and water. This process is successful in removing layers of paint, carbon, pollution, smoke damage and mold from all types of surfaces.

Dry ice cleaning is a process that uses dry ice pellets shot at high speed to clean surfaces with no impact on the substrate. The unique properties of CO2 allow you to clean any type of mold, including all grades of steel, and a variety of mold finishes up to and including A1 surfaces and textured surfaces. Using this process will help you produce higher quality parts at faster speeds while reducing costs.

Wipe out polymer buildup without damage to your production dies. Using dry ice blasting is safer and more effective than solvents or other abrasive methods.

Dry ice cleaning is an effective solution to remove burrs, flash and mold lines in machined and molded parts. Dry ice is non-abrasive, and does not create secondary waste (like abrasives), which ensures the geometries of your finished part are maintained without leaving residual media. Dry ice cleaning provides a fast, ultra-high gloss finish while also reducing post-processing time, labor and material costs.

Dry ice cleaning is a surface preparation process that does not require aqueous or chemical solutions. This process can be used to remove contaminants from delicate plastic surfaces and is also used to remove heavy contaminant buildup on metal and steel surfaces. Dry ice cleaning will not leave residue on surfaces or cause grit entrapment, which results in higher quality parts and more accurate measurements during testing.

Dry ice cleaning can reduce maintenance costs by effectively removing weld slag, spatter, resin, oil and dampering adhesive buildup from robots, production equipment and ancillary equipment.